CNC Lathe VS Conventional Lathe: What is the difference?

In the "manufacturing industry", what is called "turning work" or "Turning Process" is considered a process that is often seen. Turning work is a production process that involves the rotation of the machine to turn the material or workpiece. For the production process of turned workpieces, choosing a lathe or Lathe is very important. Factories need to choose tools and use them correctly, including choosing the type of lathe that is appropriate for each type of part, which will result in higher quality parts.

Generally, there are many types of lathes, but the most popular type at the moment is the “CNC Lathe” or “CNC Lathe”. In this article, we will compare between CNC Lathes and general lathes to see the clear differences between the two types of lathes.

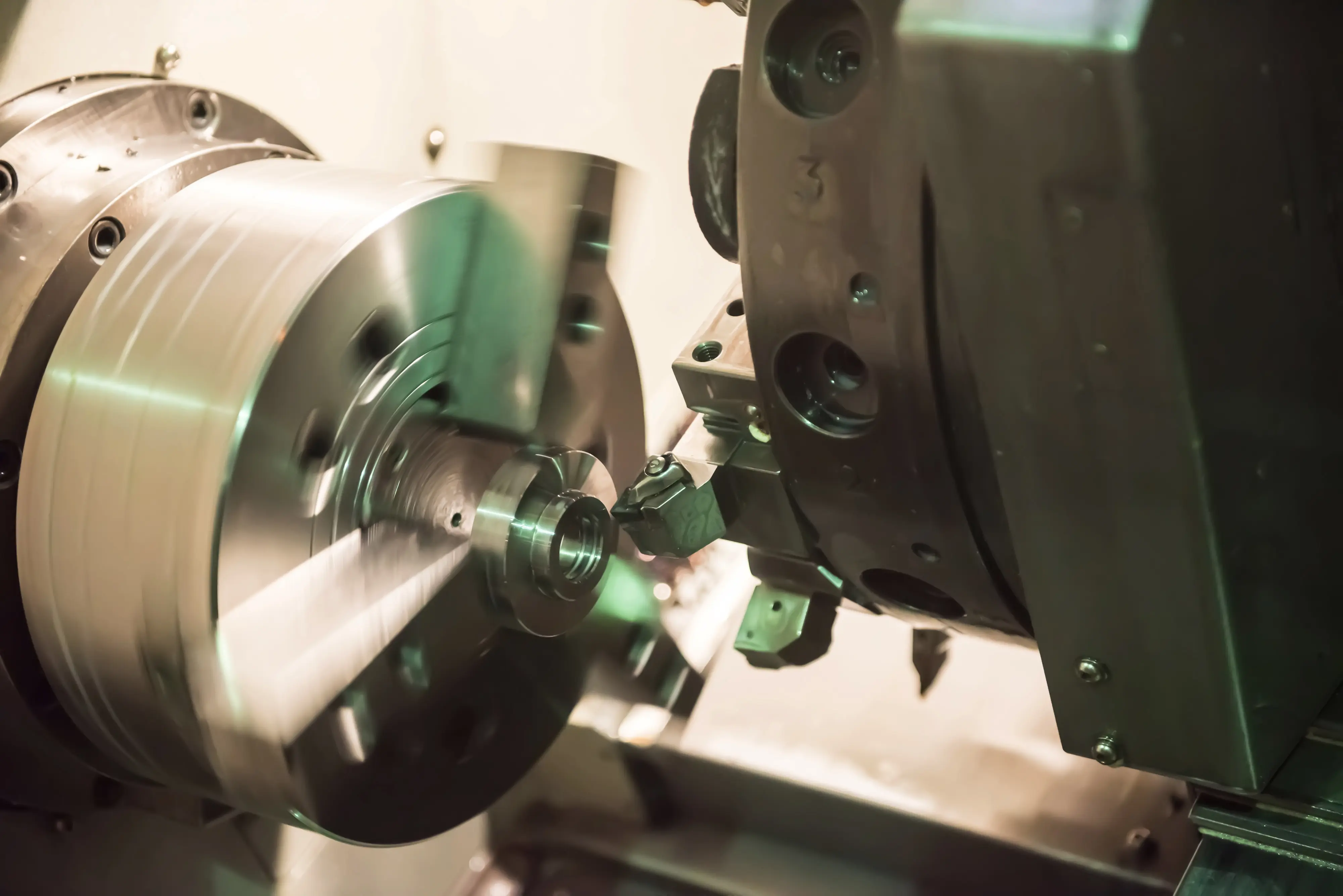

What is a CNC lathe?

A CNC lathe is a lathe that uses the CNC system or “Computer Numerical Control” to control the turning of the workpiece, allowing the production of parts to be of the desired size and shape. And because the CNC lathe is controlled by a computer system, the workpieces from the CNC lathe are detailed and precise, which is beneficial for workpieces that require complexity.

In addition, using a CNC lathe allows you to control the precision of the workpiece or material up to 0.001 mm. and can also control and command multiple lathes to work at the same time. In addition to getting workpieces that are more detailed and complex than using a general lathe, you also get multiple workpieces in one production cycle, which saves more time in work.

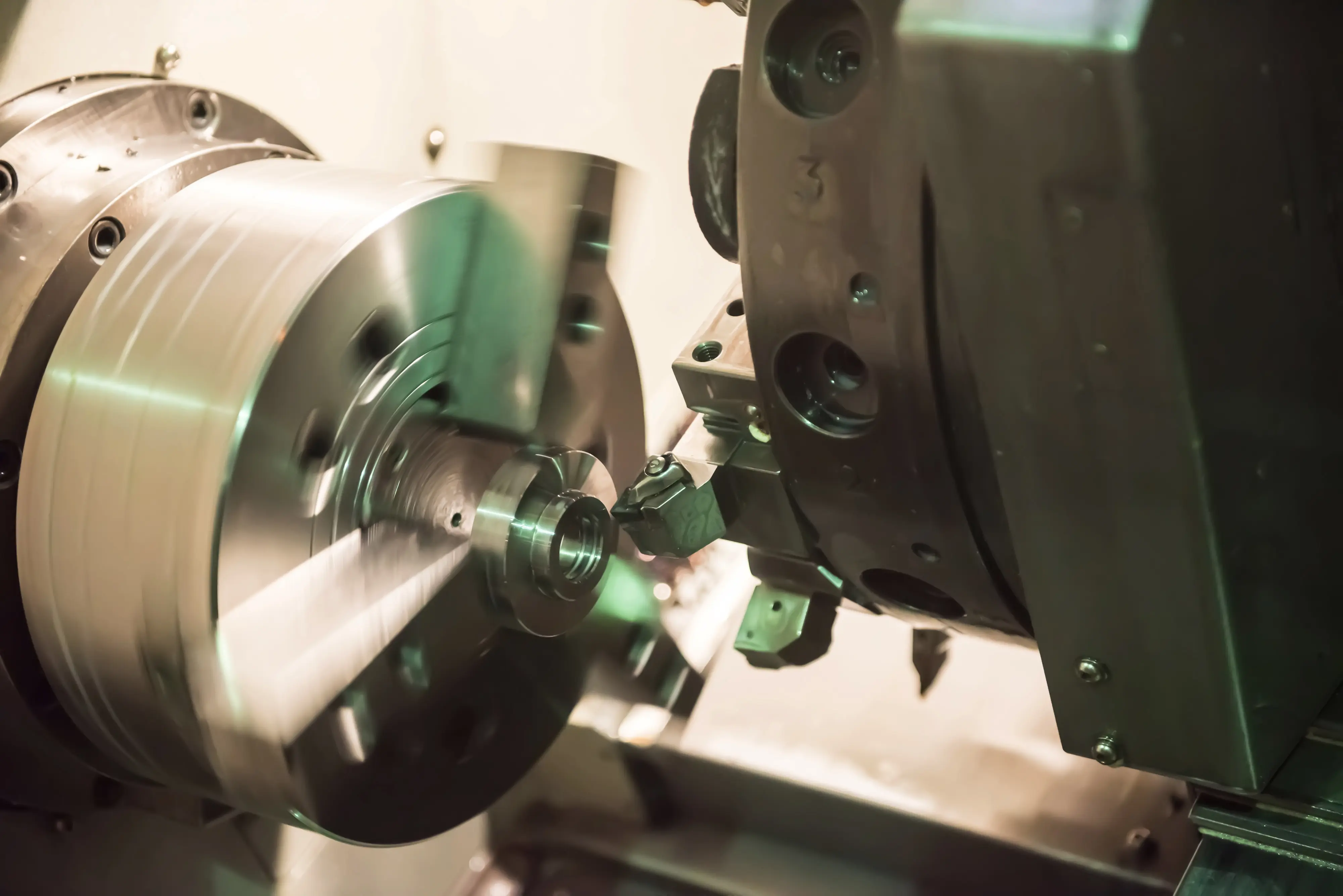

What is a general lathe?

While a CNC lathe works through computer control, a general lathe works with a technician controlling the movement of the knife by hand so that the lathe can cut the workpiece in the desired position. Or it can be said that the operation of a general lathe is "Manual" work.

Choosing a general lathe makes choosing a technician to control the machine's operation system very important. This is because the technician must constantly observe the position of the lathe, adjust the cutting position of the material, and adjust the speed and feed rate of the machine at all times. With a complex operating system, a general lathe cannot produce a large number of workpieces in a single operation and is not suitable for use with detailed work or workpieces that require high complexity.

How are these two types of lathes different?

Now that we know how these two types of lathes work, in this section we will compare the differences between CNC lathes and general lathes in a way that is easy to understand so that everyone can clearly see the differences between these two types of machines and which type of machine is suitable for producing the workpieces or materials that we want.

Budget and price

When comparing the two types of lathes, it was found that the general lathe is much cheaper than the CNC lathe because it requires human labor, does not require a computer system to control, has a simpler electrical system structure, and also has a relatively simple structure and parts of the lathe, not complicated. This makes the general lathe cheaper because it has lower production costs than the CNC lathe.

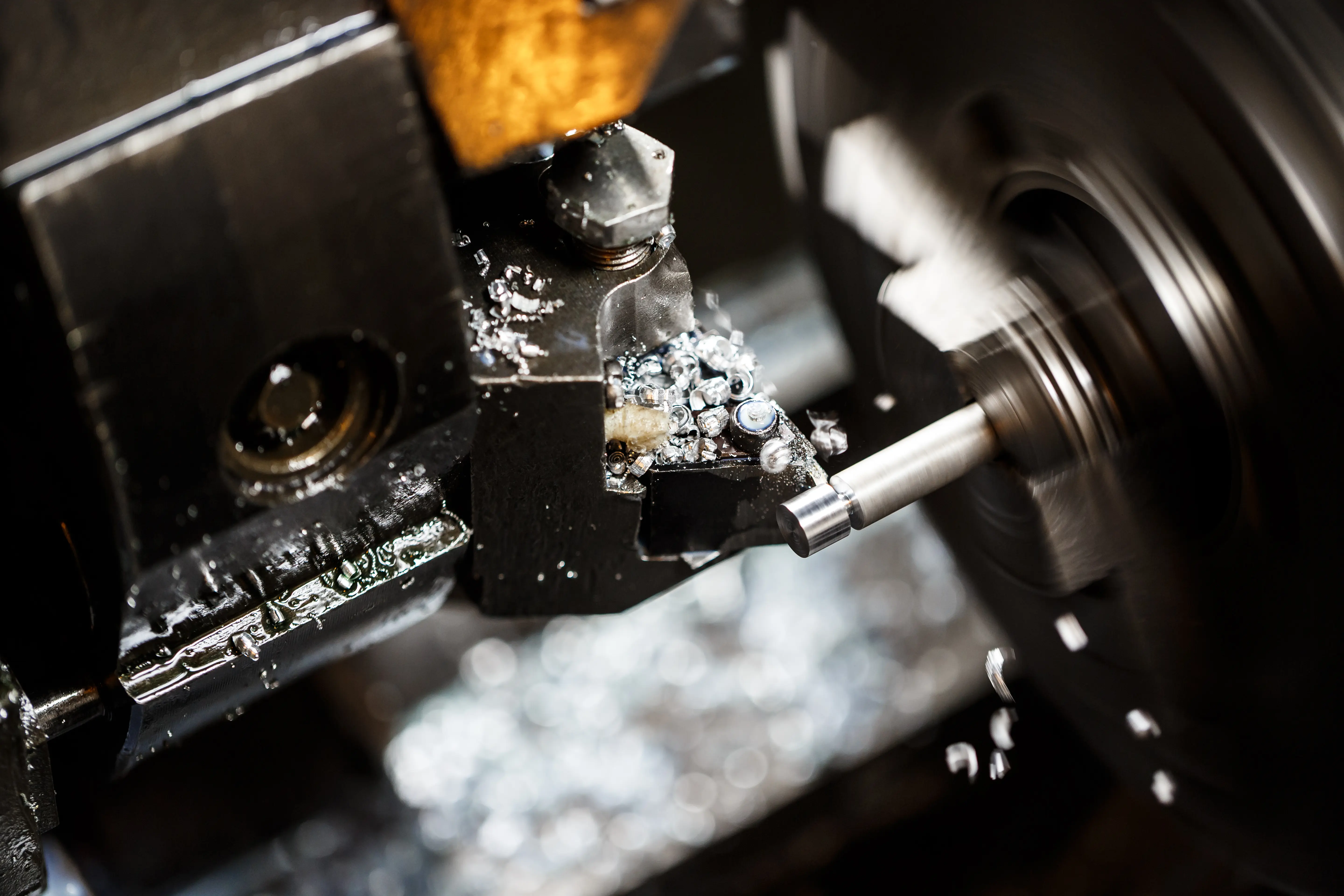

Production speed of workpieces

After comparing budget and price, another important factor to consider when choosing a lathe is “the speed of workpiece production.” A CNC lathe can produce a large number of workpieces or materials in a single order, and also produces highly accurate, detailed, and complex workpieces. Meanwhile, a general lathe cannot produce a large number of workpieces and takes a long time to produce because it still requires a technician to control the work and must stop the machine to inspect the workpiece at all times.

Controller

Both types of lathes require a technician to control the operation of the machine at all times. But the difference between these 2 lathes is the “expertise of the operator”. Since the CNC lathe is a computer-based lathe, the operator does not need to be highly skilled. When choosing a CNC lathe, the operator will only have to take the workpiece or material in and out of the machine. As a result, just 1 operator can control 2-4 machines at the same time.

On the other hand, when choosing to use a general lathe, it is necessary to choose a highly skilled operator because the operator must constantly estimate the distance of the blade, check the position before turning the blade, and adjust the speed and feed rate of the machine all the time. Therefore, choosing to use a CNC lathe can help reduce the problem of technician shortages more than anything else and also reduce the cost of hiring employees.

Conclusion

After comparing between CNC lathes and general lathes, we concluded that “CNC lathes produce workpieces or materials with a precision of up to 0.001 mm. Every workpiece produced is more detailed and consistently accurate than using general lathes, reducing the amount of waste, resulting in less waste in materials used, and also reducing production costs and hiring employees.”

And if anyone wants a piece of work or material that meets their needs, is detailed, complex, has high quality and is consistent, produced with a CNC lathe, they must choose to produce their work at "C.C.AUTOPART" because we are a metal parts manufacturing company that has been in service for a long time, for more than 34 years, with our work guaranteed by many national awards.

However, if you don't want to miss out on the production of quality work, let us advise you. We are ready to provide knowledge about metal parts from experts and have a team of skilled technicians who are always ready to serve you. In addition, if anyone is interested in 'metal forming', you can read more in the article 'Get to know "metal forming": what is it? and what are the processes?' You can continue.